Computer vision is no longer a futuristic concept confined to sci-fi books and movies. The technology is everywhere, subtly reshaping the way users interact with technology. From facial recognition on smartphones to quality inspections on factory floors, computer vision helps machines interpret and understand images, videos, and other visual inputs.

This powerful technology has proven its worth in streamlining processes and eliminating human error, raising efficiency across diverse sectors. And now, it’s ready to take the world of logistics and supply chain management by storm.

In logistics and supply chain operations, where speed, accuracy, and optimization are critical, computer vision brings a much-needed edge. Imagine autonomous vehicles safely navigating your warehouses, robots visually sorting the packages at lightning speed, and real-time tracking of products from your factory to the customer’s doorstep.

This isn’t some far-fetched reality but is already happening in various locations worldwide. As businesses deal with growing consumer demands and global market complexities, computer vision in logistics and supply chain management has emerged as a trusted ally that can bridge gaps and drive efficiency.

Many logistics businesses are already using this technology to solve common problems, such as mislabeled packages or unexpected stock shortages. With advanced image processing and analytics, teams can detect issues sooner and make smarter decisions. Some firms are even using computer vision to enhance workplace safety, spotting hazards before they cause accidents. Simply put, the rise in competition has made businesses see computer vision as a necessity rather than a luxury.

If you want to know how computer vision revolutionizes manufacturing, logistics, and supply chain management. This blog will help you see the potential of this cutting-edge technology and give you a clear idea of why it’s becoming a must-have for businesses looking to stay ahead in today’s fast-paced market.

Logistics and Supply Chain Revolution: A Glimpse into the Impact of Computer Vision

Computer vision is a technology that allows machines and software to interpret and understand visual information, such as images or videos. Logistics and supply chain management use computer vision to identify and track packages, assess product quality, and optimize warehouse operations. By automating tasks that once required a sharp human eye, computer vision reduces the chance of errors and speeds up many everyday processes.

A key advantage of computer vision in the supply chain or logistics sector is its ability to provide real-time insights. Whether scanning barcodes on a conveyor belt or monitoring stock levels in a busy warehouse, this technology delivers instant feedback. This immediate data helps companies make quick decisions, adjust workflows, and stay on schedule, which are all vital in a fast-paced environment where every second counts.

According to recent insights from McKinsey, businesses are gearing up to increase their warehouse automation investment significantly. They will allocate about 25 percent of their capital in the next five years toward computer vision, machine learning, and AI technologies. Furthermore, logistics automation using computer vision and other technologies is expected to take up over a third of capital budgets, making it the highest among all sectors.

Meanwhile, the global market for computer vision is expected to witness a CAGR of over 15% from 2025 to 2031, reaching a whopping $72.66 billion valuation. These figures underline why now is the perfect time to embrace computer vision. Simply put, organizations that invest early can stay ahead of the curve, enhance operational efficiency, and secure a competitive edge in a rapidly evolving marketplace.

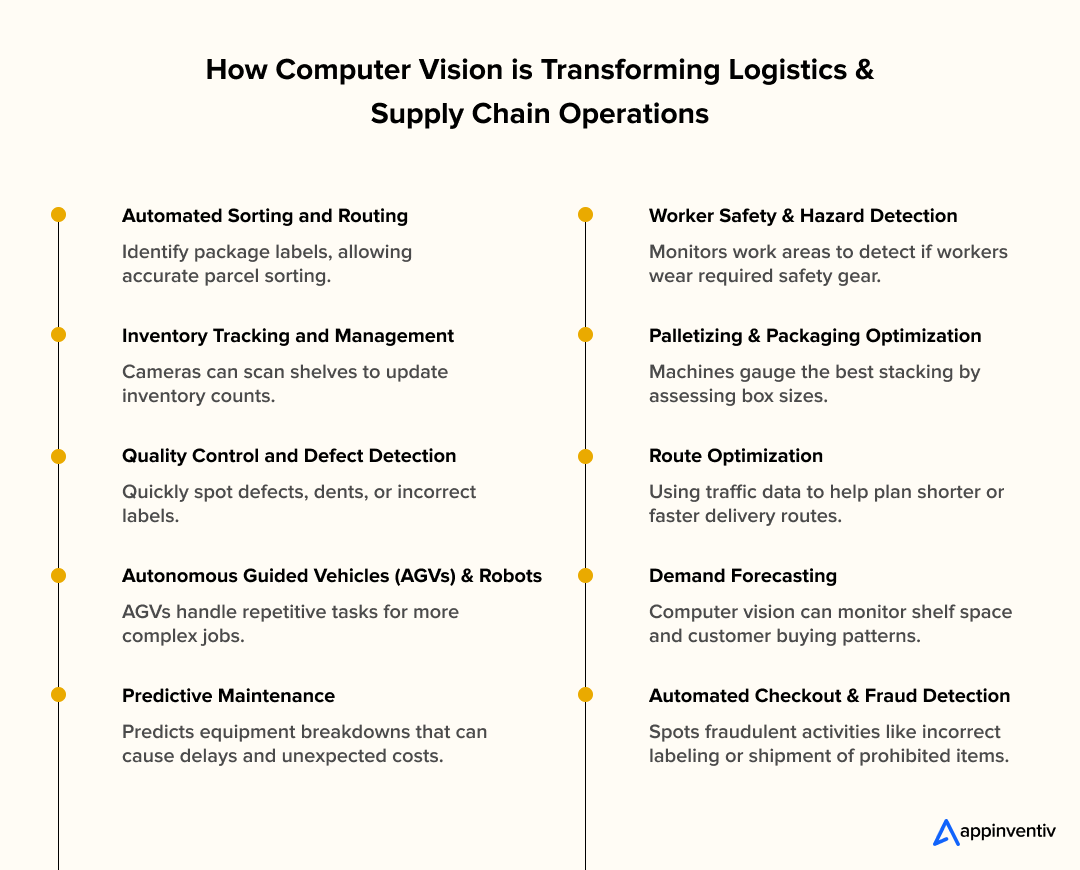

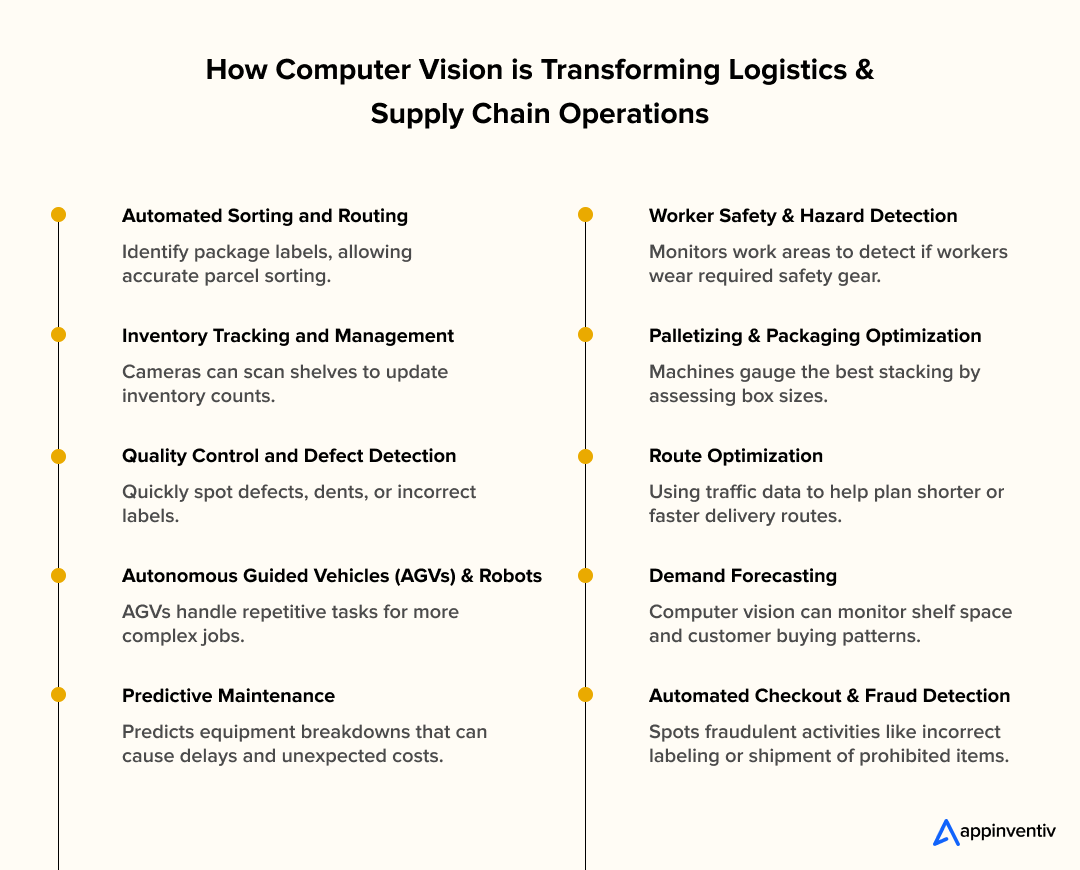

10 Use Cases and Examples of How Computer Vision is Revolutionizing Logistics and Supply Chain Management

Staying ahead requires more than efficient routes in this rapidly evolving logistics and supply chain industry. Computer vision plays a major role in helping businesses reduce errors, improve speed, and keep customers happy. Let us look at the major computer vision in logistics & supply chain use cases:

Automated Sorting and Routing

Computer vision technology can instantly scan and identify package labels, making it possible to sort thousands of parcels with near-perfect accuracy. This reduces manual work and speeds up the entire shipping process. By recognizing barcodes, QR codes, or handwritten labels, computer vision helps ensure the right package immediately goes to the right destination.

Real-World Example: DHL

DHL uses computer vision in its sorting facilities to automatically route packages to the correct conveyor belts, reducing sorting errors and delivery times.

Inventory Tracking and Management

Your business needs inventory management system software to keep track of stock levels in large warehouses, which can be tricky. With computer vision in supply chain operations, cameras can scan shelves or bins to update inventory counts in real time. If items are misplaced or stock is running low, alerts can be sent to managers immediately. This leads to fewer stockouts and a smoother supply chain flow.

Real-World Example: Amazon

Amazon employs camera-based systems in its fulfillment centers to track inventory levels, notify staff when restocking is needed, and help maintain accurate stock data.

Quality Control and Defect Detection

Quality checks are essential before products are shipped to avoid sending damaged items. Computer vision can spot defects, such as dents or incorrect labels, much faster than a manual inspection. This prevents faulty products from reaching customers and also saves time and resources.

Real-World Example: FedEx

FedEx uses computer vision tools to examine packages for damage during transit, so it can quickly replace or repack items.

Autonomous Guided Vehicles (AGVs) and Robots

Robotic vehicles powered by computer vision can navigate warehouse aisles, avoiding obstacles and mapping out efficient paths. These Autonomous Guided Vehicles handle repetitive tasks like moving items from one area to another, freeing human workers for more complex jobs. It helps lower labor costs and improve safety.

Real-World Example: Alibaba

Alibaba’s massive fulfillment centers use vision-guided robots to transport goods, reducing delivery times and improving overall efficiency.

Predictive Maintenance

Predictive maintenance is a leading use case of computer vision in logistics that hundreds of firms are leveraging. Equipment breakdowns can cause delays and unexpected costs. With computer vision, cameras can spot early signs of wear and tear on machines, such as conveyor belts or robotic arms. By acting on these warning signals, businesses can fix problems before they become major.

Real-World Example: UPS

UPS has experimented with computer vision solutions to monitor the condition of its sorting equipment, helping it schedule maintenance before any serious malfunctions occur.

Worker Safety and Hazard Detection

Busy warehouses come with various safety risks. Computer vision in transportation operations can monitor work areas to detect if workers are wearing required safety gear or entering restricted zones. It can also watch for events like spills or fallen objects, sending instant alerts to prevent accidents.

Real-World Example: Walmart

Walmart has piloted camera-based safety systems that detect when forklifts get too close to workers and issue real-time warnings to reduce the chance of collisions.

Palletizing and Packaging Optimization

Arranging boxes on pallets efficiently requires precise calculations. Computer vision helps machines gauge the best stacking method by assessing box sizes and shapes. This increases the number of items shipped in one go, saving space and cost.

Real-World Example: Bosch

Bosch uses automated systems that rely on visual data to stack items neatly, ensuring each truckload is used to its maximum capacity.

Route Optimization

It’s not just about what happens inside the warehouse; the journey matters, too. Computer vision in transportation operations can be combined with traffic data to help plan shorter or faster delivery routes. Logistics teams can avoid jams and reduce fuel consumption by analyzing visuals from onboard cameras or drones.

Real-World Example: Maersk

Maersk has started using computer vision alongside satellite data to monitor weather patterns, port traffic, and potential obstacles. This helps them choose the safest and most efficient routes for their cargo ships, reducing transit times and operational expenses.

Demand Forecasting

Demand forecasting is one of the major computer vision applications in logistics that has gained traction in the past few years. Understanding when certain products will be in high demand helps businesses stock just the right amount. Computer vision can monitor shelf space and customer buying patterns in real-time. Combining with other data sources results in accurate predictions, reducing overstock or stockouts.

Real-World Example: Kroger

Kroger, a major US supermarket chain, integrates computer vision with its analytics platform to predict when store shelves need restocking, cutting costs and improving customer satisfaction.

Automated Checkout and Fraud Detection

In retail or distribution settings, computer vision can identify items at checkout or verify package contents to prevent errors. It also helps spot fraudulent activities, such as incorrect labeling or attempts to ship prohibited items. By catching these issues early, companies save on potential losses.

Real-World Example: Amazon Go

Amazon Go is a major computer vision logistics case study that helps businesses understand how stores use a vision-based checkout system that tracks what customers pick up, letting them walk out with items automatically billed to their account, boosting convenience and security.

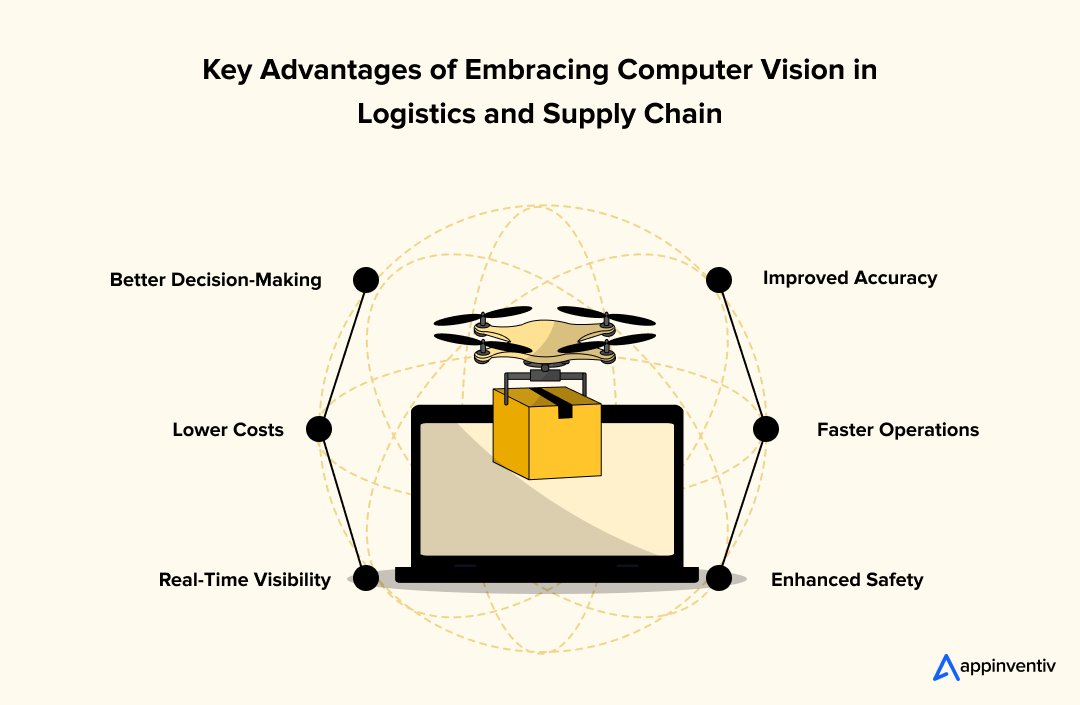

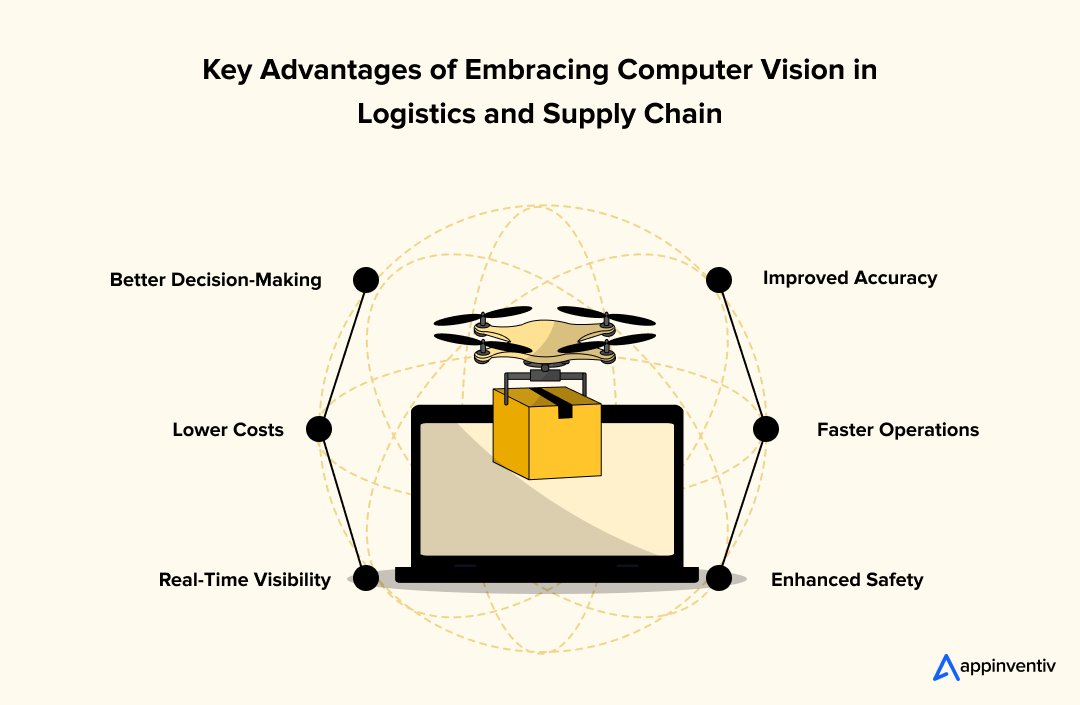

Benefits of Leveraging Computer Vision in Logistics and Supply Chain Management

With the rapid rise of eCommerce and on-demand delivery, logistics businesses need solutions that can keep up. Computer vision offers a powerful way to meet these challenges, cutting costs and creating smoother operations. Let us look at the benefits of computer vision in logistics and supply chain management in detail below:

Improved Accuracy

Computer vision can dramatically reduce manual errors, such as mislabeled packages or misplaced items. Automated systems that see and process visual data ensure that orders and inventory records stay accurate, leading to fewer customer complaints.

Faster Operations

Computer vision in supply chain and logistics operations reduces wait times by automating tasks like sorting, routing, and inspections. Workers can focus on more complex responsibilities while the machines handle repetitive jobs at higher speeds, resulting in quicker shipments and satisfied customers.

Enhanced Safety

Warehouses and distribution centers can be crowded, making accidents easy to happen. Computer vision solutions can monitor workspaces, detect hazards, and alert staff when something goes wrong. This proactive approach helps protect both employees and goods.

Real-Time Visibility

Cameras and sensors powered by computer vision can give managers up-to-the-minute insights into what’s happening across the supply chain. Whether monitoring inventory in a warehouse or checking traffic on delivery routes, real-time data helps prevent bottlenecks and delays.

Lower Costs

From catching defects early to cutting overtime hours, computer vision helps businesses save money in multiple ways. By boosting efficiency and reducing wasted materials, these systems contribute to a leaner, more cost-effective supply chain.

Better Decision-Making

With the detailed data computer vision provides, companies can make well-informed decisions faster. They can adjust staffing, modify routes, or scale operations as needed, all backed by visual evidence rather than guesswork.

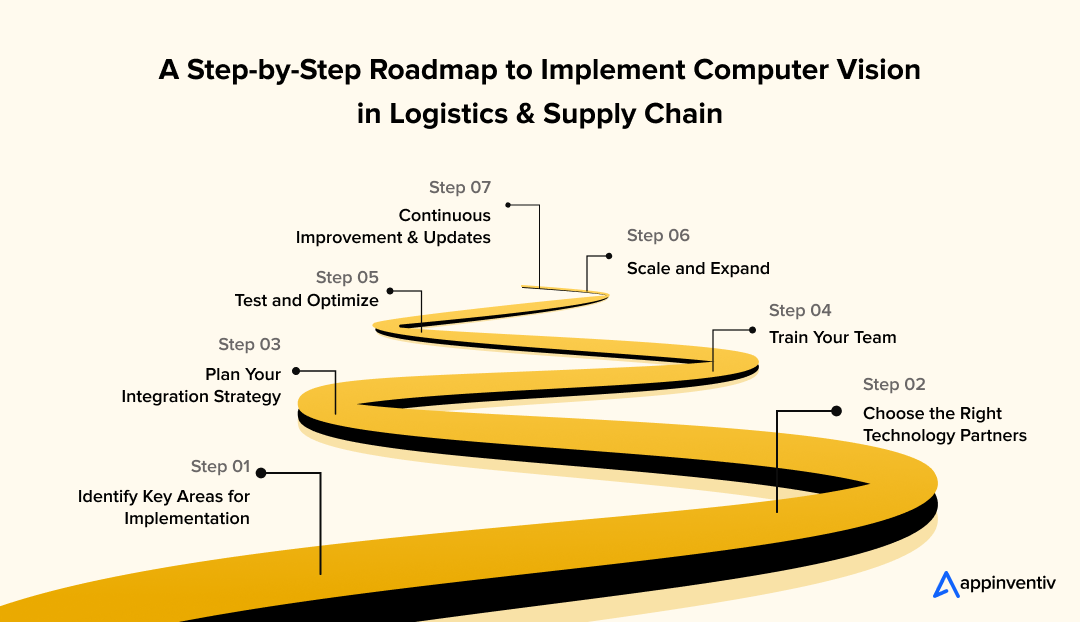

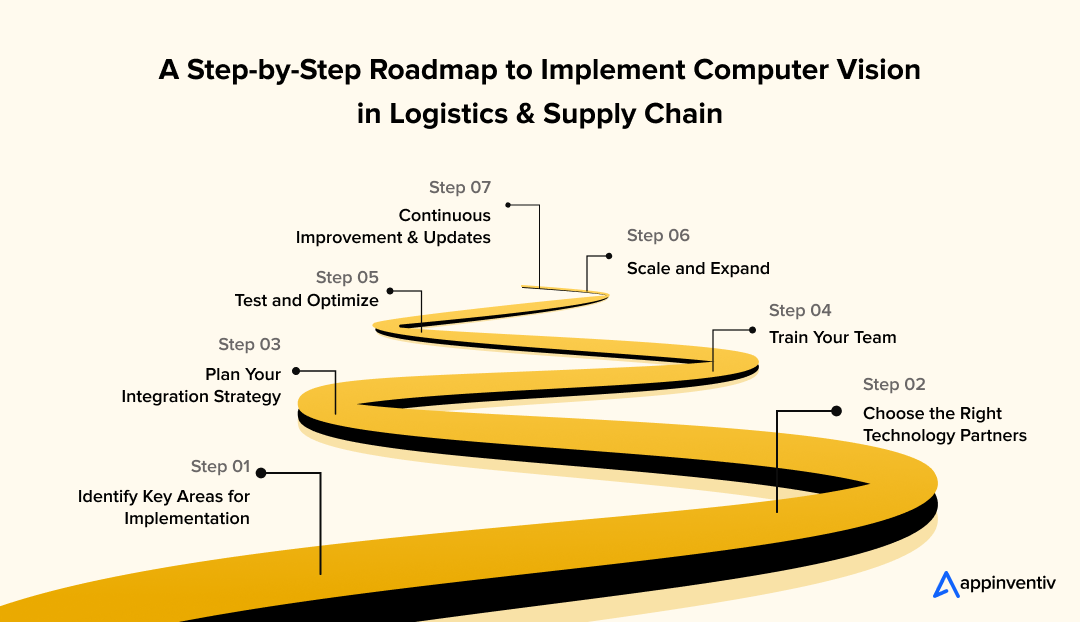

How to Integrate Computer Vision in Your Logistics and Supply Chain Operations: A Step-by-Step Guide

Implementing computer vision in logistics and supply chain operations can seem daunting, but with a structured approach, it becomes manageable. Here’s a step-by-step guide to help you integrate this transformative technology smoothly and effectively.

Identify Key Areas for Implementation

Start by pinpointing where computer vision can make the biggest impact on your operations. Common areas include inventory management, quality control, and logistics tracking. Assess these areas’ challenges and bottlenecks to understand where automation and real-time analysis could help.

Choose the Right Technology Partners

Once you know where you need computer vision, look for technology providers specializing in this field. Consider factors such as their experience in the logistics sector, the scalability of their solutions, and the support they offer. Choosing partners who provide technology and understand your business’s specific needs is important.

Plan Your Integration Strategy

Develop a detailed plan for integrating computer vision systems into your existing workflows. This should include timelines, budget forecasts, and the scope of initial deployment. Start small with a pilot project in one area to measure the effectiveness of the solutions backed by computer vision for the supply chain before rolling out the technology on a larger scale.

Train Your Team

Before fully implementing computer vision in supply chain and logistics workflows, ensure your team understands how to use the new systems. This involves training employees on the technology’s operational and technical aspects. Consider specialized training sessions for IT staff and operational teams to help them adapt to the new tools.

Test and Optimize

Run thorough tests to ensure the computer vision systems function as intended. Monitor the outcomes to see if they meet your accuracy, speed, and ROI expectations. Use the insights from the pilot project to tweak and optimize the system before expanding its use.

Scale and Expand

After successful testing and optimization, gradually scale the use of computer vision across other areas of your operations. Continuously monitor the performance and make adjustments as needed. As the technology proves its value, consider integrating more advanced computer vision capabilities or expanding its use to other parts of the supply chain.

Continuous Improvement and Updates

Technology evolves rapidly, and staying updated is crucial. Regularly review and upgrade your computer vision systems to benefit from the latest advancements.

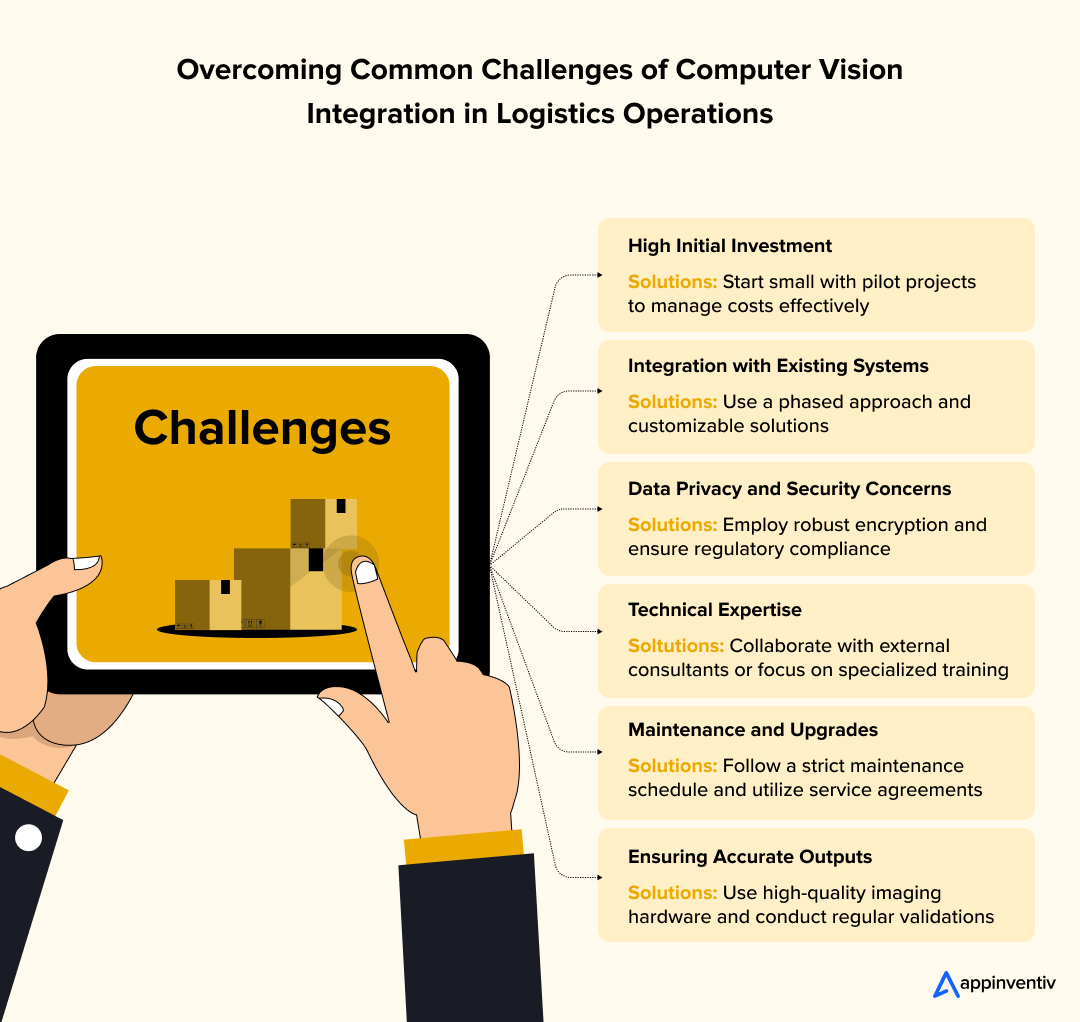

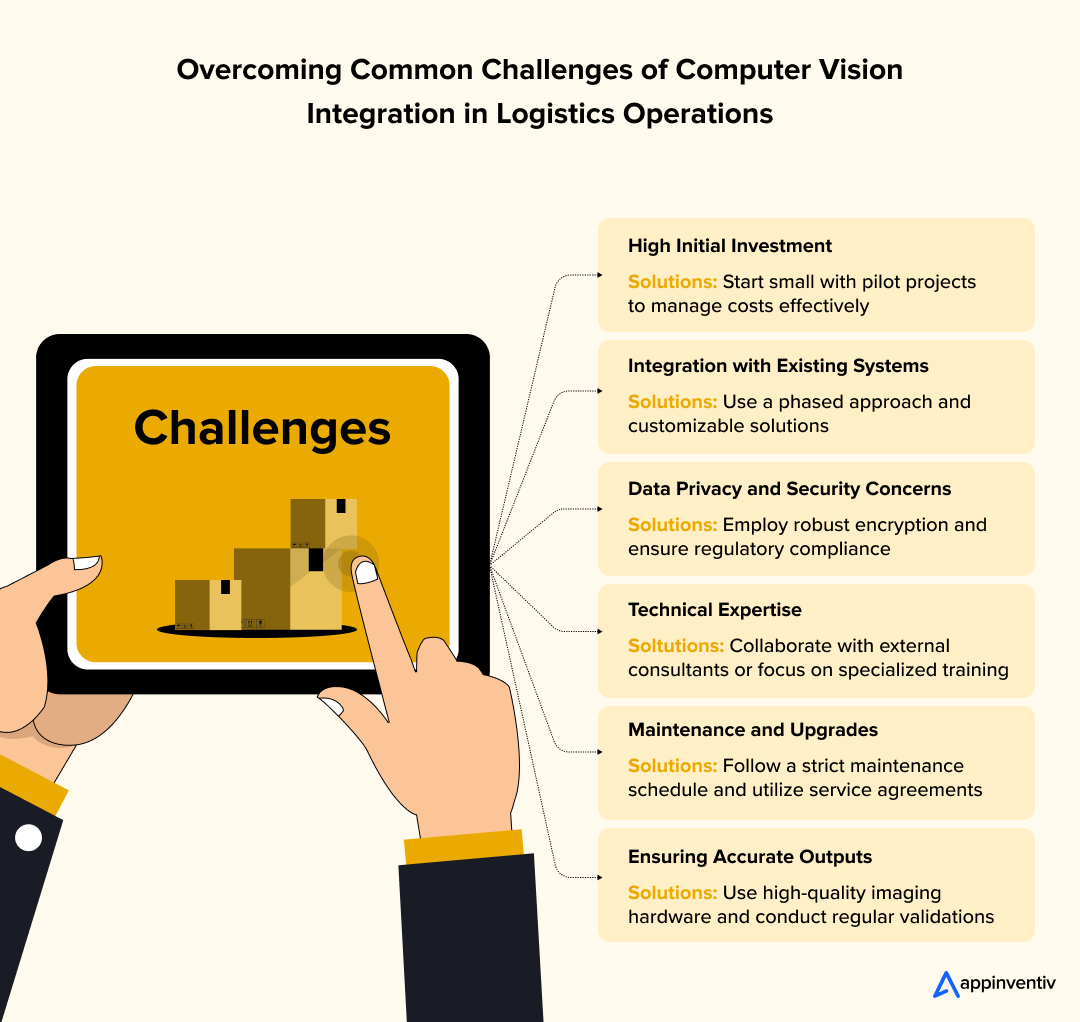

Challenges Associated with Computer Vision Integration in Logistics Operations

Integrating computer vision into logistics operations offers numerous benefits, but it’s not without its challenges. Addressing these effectively is key to unlocking the full potential of this technology. Let us look at the challenges of computer vision in logistics in detail below:

High Initial Investment

Implementing computer vision systems requires significant upfront costs. This includes the technology and infrastructure upgrades needed to support these advanced systems.

Solution: To mitigate the impact of high initial costs, companies can start with pilot projects that require minimal investment and provide better ROI. This approach allows businesses to scale their investment as they see results, making it easier to justify and manage costs.

Integration with Existing Systems

Integrating new computer vision technologies with existing IT systems and workflows can be complex. Compatibility issues may arise, disrupting current operations.

Solution: Work closely with development experts who offer customizable solutions that can be adapted to fit into existing systems. Additionally, a phased integration approach will allow for addressing potential compatibility issues on a smaller scale before a full rollout.

Data Privacy and Security Concerns

Using computer vision in logistics often involves processing large volumes of sensitive data, raising concerns about privacy and security.

Solution: Implement robust cybersecurity measures, including data encryption and secure access protocols. To protect customer and business data, it’s also important to ensure compliance with local and international data protection regulations.

Technical Expertise

Computer vision technology requires certain technical expertise, which might not be readily available within all organizations.

Solution: Consider partnering with external consultants who can provide the necessary technical support.

Maintenance and Upgrades

Maintaining and upgrading computer vision systems can be challenging as technology rapidly advances. Regular updates and maintenance are required to ensure efficiency and reliability.

Solution: Establish a maintenance schedule and stick to it. Keep systems updated with the latest software improvements. Consider service agreements with development providers to ensure ongoing support and updates.

Ensuring Accurate Outputs

Computer vision systems rely heavily on the quality of input data. Poor-quality images or incorrect settings can lead to inaccurate outputs, affecting decision-making.

Solution: Regular validation of the systems helps ensure accuracy. High-quality cameras and sensors are also crucial to capture the best possible inputs.

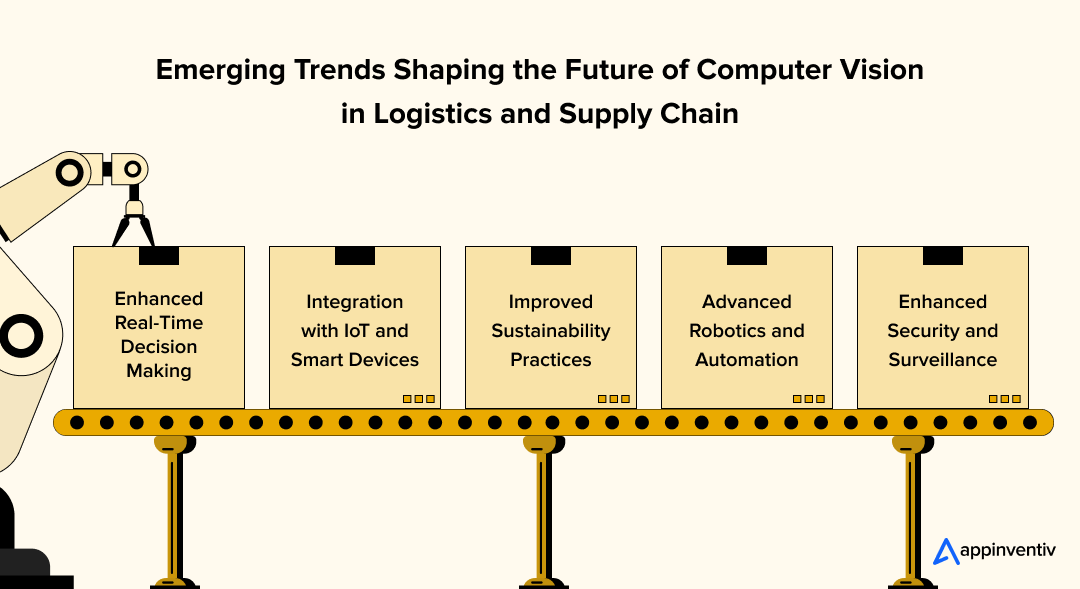

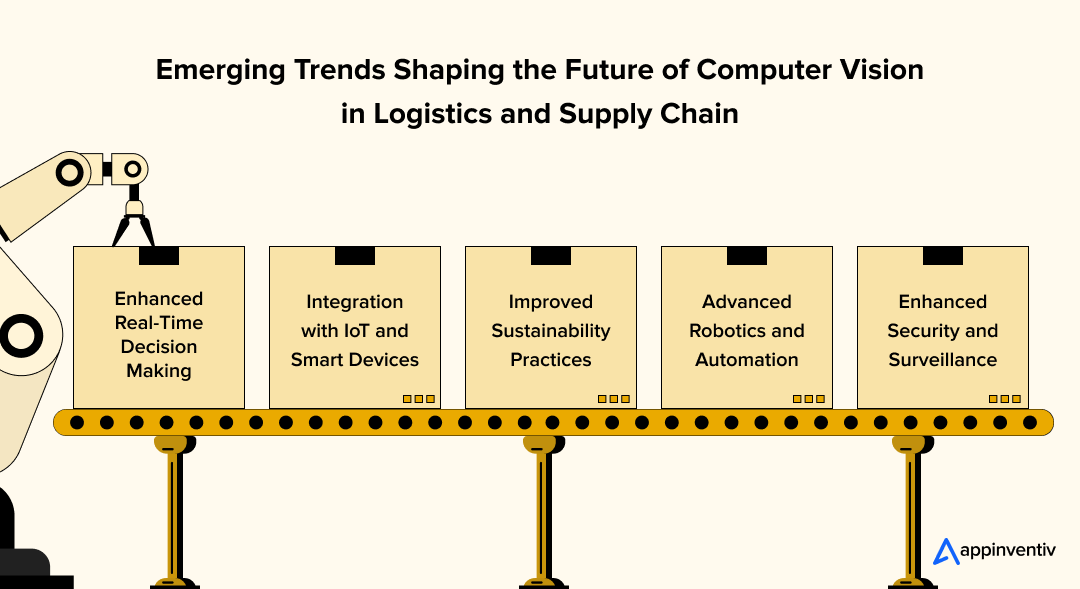

Future Trends That Will Revolutionize Computer Vision in the Logistics and Supply Chain Industry

As technology advances rapidly, the logistics and supply chain industry can expect further transformation. The integration of computer vision for supply chain operations is already reshaping the sector, and future trends promise to deepen this impact, bringing more efficiency and innovation.

Enhanced Real-Time Decision Making

Computer vision technology will enable even faster and more accurate real-time decision-making in logistics operations as it becomes more sophisticated. This involves instant visual data analysis from drones, cameras, and sensors to adjust workflows and processes immediately.

Integration with IoT and Smart Devices

Integrating computer vision with the Internet of Things (IoT) and other smart devices will create a more interconnected and automated logistics environment. This will allow for seamless data exchange and more coordinated actions across various supply chain components.

Improved Sustainability Practices

Sustainability is becoming a priority for many companies, and computer vision can make logistics operations more environmentally friendly. By optimizing routes and reducing wasted resources, these technologies can help minimize carbon footprints.

Advanced Robotics and Automation

Advanced robotics, powered by computer vision, will continue to grow, further automating warehouses and distribution centers. These robots will perform a wider range of tasks, from picking and packing to more complex manipulations that require human intervention.

Enhanced Security and Surveillance

Computer vision in the logistics and supply chain sectors will increasingly enhance security and surveillance. More sophisticated image recognition technologies will detect unauthorized access or suspicious activities in sensitive areas like warehouses or during transit.

How Can Appinventiv Help Businesses Across the Logistics Sector Leverage Computer Vision

We hope our blog has helped you understand everything related to computer vision in logistics and supply chain management. Now, to fully harness the potential of these technologies, it’s crucial to choose the right partner who can guide you through the complexities of integration and implementation. As a leading computer vision development services firm, here’s how we can help your business excel in this transformative journey:

Expertise and Experience

We have a proven track record of delivering cutting-edge technology solutions across various industries, including logistics. Our team of experts specializes in the latest computer vision technologies, ensuring we can tailor a solution that meets your logistics operations’ unique needs and challenges.

Customized Solutions

We understand that each business has its own set of requirements and challenges. We pride ourselves on our ability to develop customized solutions backed by computer vision for logistics and supply chain sectors that are both efficient and scalable. Whether improving inventory accuracy, enhancing supply chain visibility, or optimizing delivery routes, we design solutions that align with your business goals.

Seamless Integration

Integrating new technologies can be daunting, especially when it involves existing complex systems. As a leading logistics software development services provider, our experts ensure a smooth integration process, minimizing disruptions to your current operations. Our strategic approach involves thoroughly assessing your infrastructure, followed by a step-by-step integration plan executed precisely.

Ongoing Support and Maintenance

Our relationship with clients doesn’t end with deployment. We provide continuous support and maintenance to ensure the computer vision systems function optimally. We offer regular updates and technical support to help you adapt to evolving market conditions and technological advancements, helping you stay competitive.

Contact us to navigate the future of computer vision in supply chain management and logistics with powerful solutions that deliver real results.

FAQs

Q. How is computer vision used in logistics?

A. Computer vision in logistics automates and streamlines various operations. It helps in tasks such as automated package sorting and routing, where it scans and recognizes labels to sort parcels quickly and accurately.

It also plays a crucial role in inventory management by monitoring stock levels through real-time image analysis. Additionally, computer vision for logistics is also used for quality control, ensuring that outgoing shipments are in good condition, and operating autonomous guided vehicles within warehouses, enhancing efficiency and safety.

Q. What is the cost of developing computer vision solutions for logistics businesses?

A. The cost of developing solutions powered by computer vision for logistics businesses can typically range from $35,000 to $200,000. The cost depends on several factors, including the complexity of the tasks, the scale of deployment, the level of customization needed, and more.

A dedicated development firm with expertise in the field can offer you the exact cost of computer vision in logistics solutions according to your custom business requirements.

Q. What is the role of computer vision in supply chain management?

A. Computer vision significantly enhances the capabilities of supply chain management by providing:

- Efficiency Improvements: Speeds up processes like sorting, packaging, and quality checks.

- Accuracy in Tracking: Ensures accurate tracking of goods throughout the supply chain, reducing losses and misplacements.

- Cost Reduction: Minimizes labor costs and error-related losses, improving overall profitability.

- Enhanced Security: Monitors goods and detects unauthorized access or tampering, ensuring product safety.

- Predictive Maintenance: It helps maintain equipment by identifying potential failures before they occur, avoiding costly downtime. Computer vision thus serves as a transformative force, optimizing operations from production to delivery.

Product Development & Engineering

IT Managed & Outsourcing

Consulting Services

Data Services

Didn't find what you're looking for? Let us know your needs, and we'll tailor a solution just for you.